A Review of Nanoindentation Continuous Stiffness Measurement Technique and Its Applications

The nanoindentation experiments tin be performed in several modes depending on the fabric properties desired. The ISO method is used to check the calibrations of the system while continuous stiffness measurements provide the depth-dependent properties. The viscoelastic response can exist characterized by measuring the complex modulus of the material while performing frequency sweeps over the desired range. The fatigue testing can be performed in the circadian indentation way to measure the fatigue/fracture life of materials.

Tabular array of Contents

- How does a Nanoindenter work?

- Continuous Stiffness Measurement

- High Temperature Nanoindentation

- Traditional Tests

- Uniaxial Tensile Tests

- Shear Tests

- Fracture Tests

3D and 4D maps provide an excellent manner to characterize the surfaces of heterogeneous materials. It is also useful when a large data ready is needed for the statistical assay of materials. The thin film properties are measured by our advanced belittling solutions to remove the substrate effect in the data. The scratch resistance and agglutinative force measurements enable users to perform various analyses in many research, industrial and educational settings.

How does a Nanoindenter work?

Nanoindentation is the latest technology that enables researchers to measure mechanical backdrop such as modulus and hardness of materials in different shapes, sizes and scales. Most notably, this technique does not demand whatsoever sample preparation and tin can measure properties for diverse materials ranging from difficult superalloys to soft biomaterials inside seconds making information technology the fastest technique for such measurements. It is a meaning development over regular uniaxial tensile and shear testing methods that take days from samples preparation to final results.

Nanoindentation is used in universities and industries to narrate thin films in electronics and packaging products, advances alloys for cutting tools, coatings for thermal barriers, viscoelastic properties of polymers, microhardness in industrial quality and command, scratch and wear resistance and many more. The bones measurements needed to perform nanoindentation are Load and depth during the experiments. The indenters of different geometries such as Berkovich for Due east and H, spherical for stress-strain, flat punch for complex modulus, cube corner for fracture toughness, spherical cone for scratch measurements, wedge for 3 point angle can be used to measure out the backdrop a user is interested in.

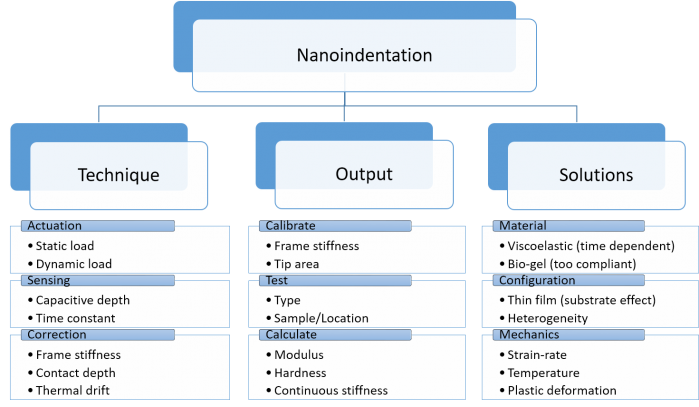

A pictorial summary of the nanoindentation procedure is given in the figure beneath which points out all the necessary steps needed and performed during the nanoindentation process. The technique involves an actuation process to utilize a load, sensing the displacements then applying the corrections needed. The output is the raw data which is calibrated for the frame stiffness, the tests are performed on the specified sites with micrometer spatial distribution and the properties are later calculated. The solutions are divided based on the type of material to give elastic, viscoelastic and soft textile properties. Configuration dependent properties for thin films, heterogeneous alloys/composites, layered materials, irradiated/estrus treated zones can be calculated as well. The nanoindentation besides provides rate dependent, temperature dependent and plasticity dependent such equally fracture toughness measurements. This makes nanoindentation the most versatile tool available for the mechanical characterization of materials.

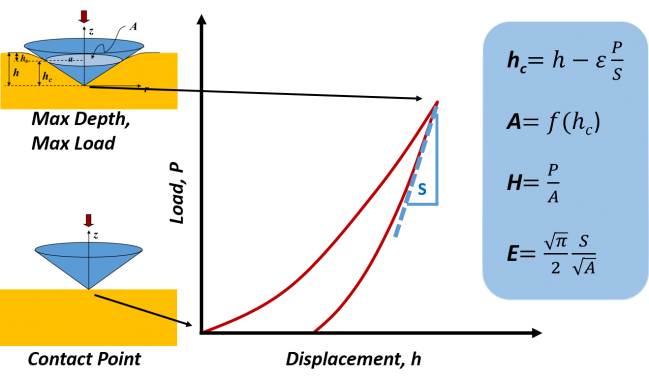

Later on pointing out many advantages of this technique, the next question that needs to be answered is how nanoindentation works. The success of this technique depends on the understanding of contact mechanics and availability of advanced data acquisition tools. The basic idea is that when we probe a textile with a very small probe/indenter, the material properties can be predicted based on the interaction of the probe with the material. The physics behind this goes back to 1800's when Hertz, Sneddon and many other researchers developed the necessary contact mechanics for ii-body contact but information technology was not until 1990's when Oliver and Pharr took information technology a step further and found a mode to measure the modulus and hardness of a material based on its contact with another known material. In the most commonly used indenters, that known material is diamond.

The diamond probe with a tip as pocket-sized as 100 nm is used to indent the surface of a sample. The load practical to the tip and the depth of penetration is subsequently measured during the process. The indentation depth is used to summate the expanse of the tip that was in contact during the indentation. This area is used to measure the hardness of the cloth.

On the other hand, unloading portion of the load-depth data contains the information of the stiffness of the textile beingness tested. Information technology is related to the contact area. Once we know the stiffness and contact area, nosotros tin can calculate the reduced modulus of the organisation.

Continuous Stiffness Measurement

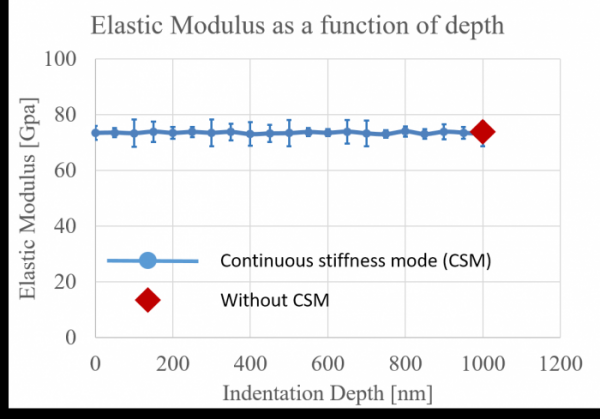

In conventional quasi-static indentation testing, the stiffness of contact is determined past analyzing the force vs. displacement curve during unloading. This depth-sensing method provides a single measurement for the given indentation depth.

The Continuous stiffness measurement (CSM) technique is a revolutionary step in the mechanical belongings measurement of materials. Information technology allows the measurement of depth-dependent properties of materials in a single step. The method involves applying a dynamic load on the top of the static load while loading. The dynamic role of the load is then used to measure the stiffness which is further processed to calculate the modulus and hardness of the material.

The CSM method offers a means of separating the in-phase and out-of-phase components of the load-displacement history. The separation provides an accurate measurement of the location of initial surface contact and continuous measurement of contact stiffness as a role of depth or frequency, thus eliminating the need for unloading cycles. This makes continuous stiffness measurement a powerful tool not but for potent materials such as metals, alloys, and ceramics simply as well for time-dependent materials like polymers, structural composites, and biomedical materials. Indentation tests using CSM can be controlled with a constant strain charge per unit, a critical test parameter for cloth systems such as pure metals or low-melting-bespeak alloys, and polymer films and film/substrate systems.

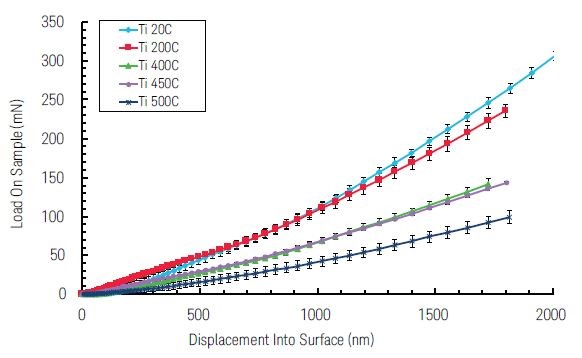

High Temperature Nanoindentation

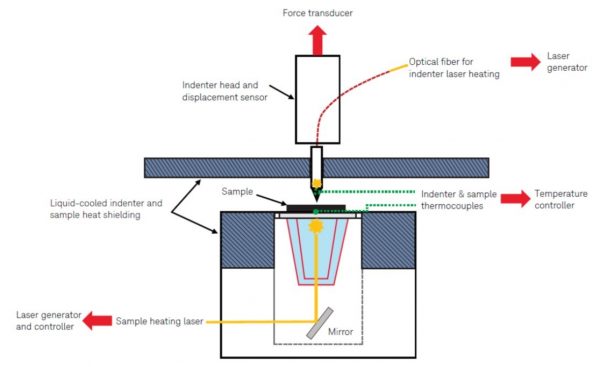

It is difficult to maintain temperature without thermal drifts in a loftier-temperature experiment. When fourth dimension or temperature dependent deformation occurs, it becomes difficult to decouple creep and elastic recovery during the unloading segment of a quasi-static test for the calculation of stiffness. So, as opposed to measuring the stiffness from unloading the material, the CSM technique imposes harmonic deportation oscillation during the hold period at peak indentation force to mensurate high-temperature properties.

Loftier-temperature nanoindentation allows for controlled temperatures and the power to test samples under dynamic temperature atmospheric condition. A laser-heated indenter tip prevents disturbance of substrate temperature during measurement. Infrequent precision on continous stiffness measurements tin can be accomplished by keeping the tip and sample at the aforementioned temperature.

Traditional Tests

Material testing is one of the nearly of import steps in new cloth development as well as production development. Nanoindentation is now the most versatile and preferred method of performing experiments to measure properties such as modulus, hardness, fracture toughness etc.

Over the last century, diverse experiments had been in practice such equally uniaxial tests to measure elastic modulus and tensile force, shear tests to measure the shear strength and crevice propagation tests to measure the fracture toughness. All these tests need elaborate sample training and are fourth dimension-consuming. The basic clarification of these tests is given below.

Uniaxial Tensile Tests

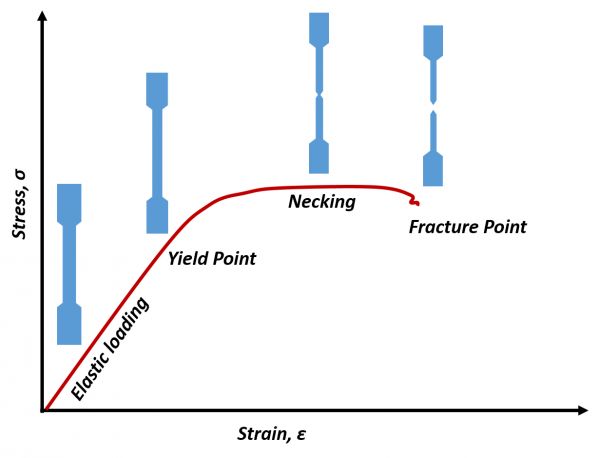

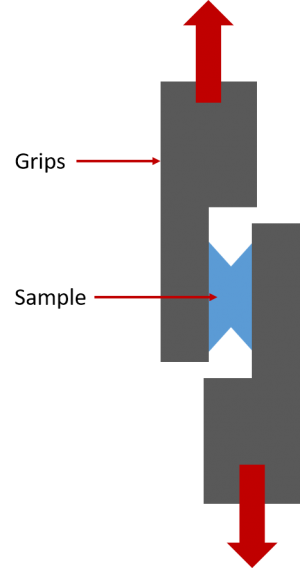

The uniaxial tensile tests are performed to measure rubberband modulus and ultimate tensile strength of materials. The test specimens are dog bone shaped as per the ASTM E8 standards. The tests are performed in displacement controlled way with the load existence monitored by load cells. As the loading continues, the specimen starts to deform elastically followed by plastic deformation which and so starts necking and ultimately fails by fracturing.

The strain during the test is calculated as the change in the approximate length divided by the original length.

The stress is calculated as the load divided by the cross-department area of the specimen.

Shear Tests

The shear tests are practical using the same loading principles as the uniaxial tension tests but with modified loading grips that transforms the load in the shear direction. There are multiple means to utilize these kinds of loads. The specimens are prepared according to ASTM standards and loaded in either displacement controlled or force controlled way. The shear modulus and shear strength of the material are measured from these tests.

Equally the loading continues, the specimen starts to deform elastically followed past plastic deformation in shear direction which then starts cracking and ultimately fails past fracturing.

Fracture Tests

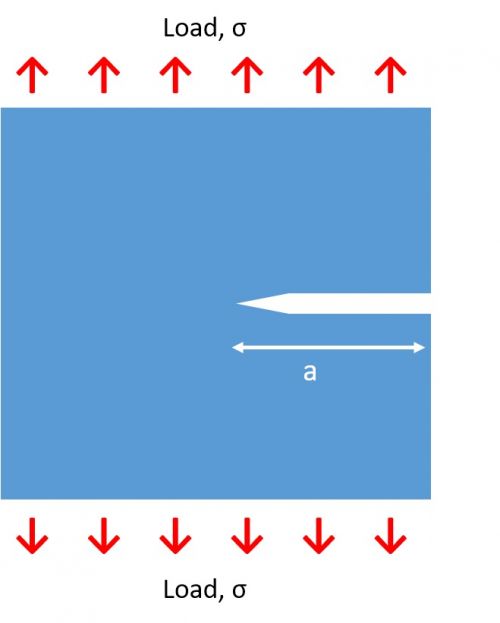

The fracture toughness of a material is measured by scissure propagation tests. The sample is prepared every bit per ASTM standards with a pre-crack in it. The sample is loaded in the lateral direction of the crack. As the crevice propagates, both the load and the cleft propagation speed is monitored which is further used to discover the fracture toughness of the fabric.

In general terms, fracture toughness is the resistance of the fabric to the propagation of the scissure. A fissure could propagate in three modes: Mode I – tensile mode, when the stress is perpendicular to the crack, Mode two – shear mode, when the practical stress is in shear direction (in-plane shear), Mode 3 – tear fashion, when the applied stress is in twist direction (out of plane shear).

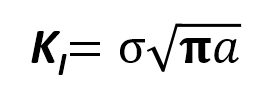

The stress at the scissure tip is divers by a term chosen stress intensity factor defined as:

The stress intensity factor at which crevice starts to propagate is called the critical stress intensity factor which is equivalent to the fracture toughness of the fabric.

maxwellhillowitich.blogspot.com

Source: https://www.nanoscience.com/techniques/nanoindentation/

0 Response to "A Review of Nanoindentation Continuous Stiffness Measurement Technique and Its Applications"

Post a Comment